ROM Roll Up Doors Series IV

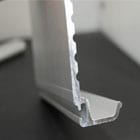

The new Series IV roll up door offers a stronger lift bar that will not bow or bend, an over-molded idler wheel for quieter operation, an improved inner seal for enhanced performance, and a grooved finger pull plate for improved grip. These are just a few of the many enhancements that make the Series IV the door preferred by first responders.

R·O·M engineers roll-up doors to last. We recognize that these doors will be put to the test each day that they are in the field, and R·O·M doors are built to meet that test.

R·O·M engineers roll-up doors to last. We recognize that these doors will be put to the test each day that they are in the field, and R·O·M doors are built to meet that test.